Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

For project integrators and engineers, choosing an Energy Storage System (ESS) is an exercise in risk management and performance optimization. While consumers might only look at the kilowatt-hour (kWh) price, professionals understand that the true value lies in the Depth of Discharge (DoD), round-trip efficiency, and the granularity of the Battery Management System (BMS).

At JL Power, we design our EOS Series batteries with a “system-first” engineering philosophy. This article explores the technical architecture that allows our systems to outperform standard market offerings in both durability and integration.

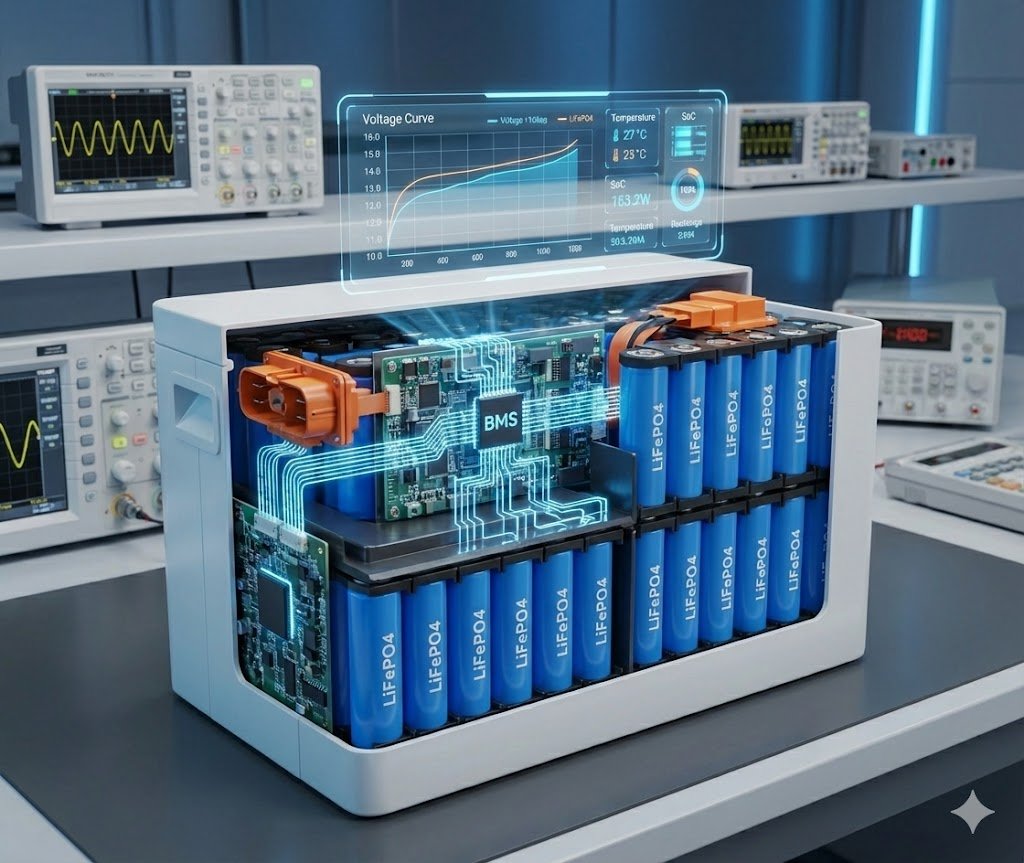

The safety and longevity of an ESS start at the molecular level. JL Power exclusively utilizes Lithium Iron Phosphate (LiFePO4) chemistry, widely recognized as the safest lithium-ion variant for stationary storage due to its high thermal runaway threshold.

A battery pack is only as strong as its weakest cell. In our manufacturing process:

An ESS is more than a container for energy; it is a complex power electronics device. The JL Power Smart BMS acts as the central nervous system, monitoring every cell in real-time.

For integrators, the biggest technical hurdle is often inverter-battery handshaking. Our BMS comes pre-loaded with firmware supporting multiple communication protocols (CAN, RS485). This ensures “Plug-and-Play” compatibility with:

Australian installations often face extreme environmental stress, from the salt spray of coastal NSW to the intense heat of the interior.

While many competitors offer IP21 or IP54 ratings (suitable only for clean, indoor environments), our EOS Series is rated IP65.

Heat is the primary enemy of lithium batteries. Our mechanical design incorporates:

From an EPC perspective, labor is a major cost driver. A battery that takes four hours to commission is twice as expensive as one that takes two.

We have eliminated complex wiring looms. Our systems feature:

| Parameter | Specification (EOS Series) |

| Nominal Voltage | 51.2 V |

| Standard Charge/Discharge | 0.5C / 1.0C (Project Dependent) |

| Peak Discharge (3s) | Up to 200A |

| Operating Temp (Charge) | 0°C to 55°C |

| Communication Interface | RS485, CAN, RS232 |

| Parallel Capability | Up to 16 units (Master-Slave Configuration) |

For project integrators, JL Power represents more than just a hardware supplier. We provide the technical documentation, the compliance assurance (IEC 62619, CE, UN38.3), and the engineering support necessary to deliver high-availability energy storage solutions.

By focusing on cell consistency, BMS intelligence, and mechanical resilience, we ensure that your projects remain operational, profitable, and safe for decades to reach.

Are you designing a project that requires specific technical parameters or custom BMS integration? Contact our engineering team today.

Ultrapower Australia Pty Ltd

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.